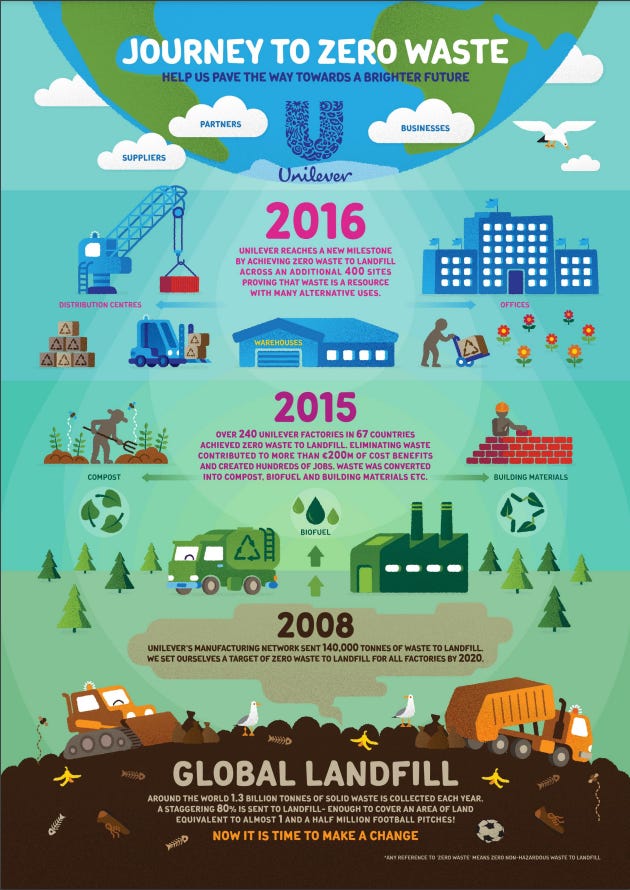

Unilever Sent 140,000 Tonnes of Waste to Landfill (in 2008)

and that's when they realized that 'business as usual' needed change.

From Trash Mountain to Zero Waste: Unilever's Pioneering Journey

In 2008, a staggering 140,000 tonnes of waste piled out of Unilever's factories.

To put that in perspective, it's roughly the weight of 17 Eiffel Towers!

This stark reality sparked a monumental shift within the multinational consumer goods giant.

Unilever embarked on an ambitious mission to achieve zero non-hazardous waste to landfill, aiming to not only manage their existing waste stream but also minimize it in the face of projected growth.

The initial target was audacious – to achieve zero waste by 2020.

But Unilever, fueled by environmental responsibility and a commitment to a circular economy, surprised even themselves by exceeding that goal by a significant margin.

Their journey to zero waste is a testament to innovative solutions, employee engagement, and the power of collaboration.

Early Victories and a Replicable Model

The quest for zero waste began in the United Kingdom.

Unilever consolidated their manufacturing waste management by transitioning from multiple local contractors to a single, nationwide partner. This centralized approach streamlined operations and facilitated waste reduction efforts.

The success in the UK proved to be a blueprint for similar implementations across Europe and later, North America.

In developed countries, the primary solutions involved traditional recycling and diverting residual waste streams into energy production.

Over half of the waste was successfully managed through these established methods.

However, replicating this approach in developing countries presented a different set of challenges.

Innovation Blooms in Diverse Landscapes

Unilever encountered unique hurdles in developing nations.

Geopolitical instability, limited infrastructure, and complex social environments demanded unconventional solutions.

Here, the company's commitment to zero waste truly blossomed into a showcase of local ingenuity.

👉 In the Philippines, a resourceful approach turned wastewater treatment sludge into a surprising new product: decorative building blocks.

This not only diverted waste but also created a useful and sustainable material for construction.

👉 Similarly, Kenya found a clever use for laminated wrapper waste – repurposing it into a versatile building material for roofing and fencing.

Distance played a crucial role in waste management for locations like Russia and Australia.

👉 Here, Unilever fostered collaboration with suppliers who collected waste materials for reblending into usable products.

This not only tackled the waste challenge but also strengthened relationships within the supply chain.

Beyond Efficiency: The Unexpected Benefits

The focus on zero waste wasn't just about environmental responsibility. It turned out to be a surprisingly profitable endeavor.

The increased use of recycled cardboard alone resulted in emission reductions equivalent to taking 10,000 cars off the road.

Additionally, by diverting waste from landfills and exploring alternative solutions, Unilever saved a significant amount of money, estimated at €220 million.

But the benefits extended far beyond financial gains.

The zero-waste initiative inadvertently created new job opportunities. As the program gained momentum, it demanded a shift in how waste was handled and managed, leading to the creation of over 1,000 jobs across the globe.

The Power of Storytelling and Shared Knowledge

Unilever understood that achieving zero waste wasn't solely about implementing technical solutions.

It was equally important to foster a sense of ownership and engagement among employees.

They encouraged their people to share their waste-reduction stories and best practices.

This "viral effect" within the company transcended national boundaries and factory floors.

Employees began to take ownership of the zero-waste mission, not just because it was company policy, but because they were invested in the environmental and economic benefits it offered.

Looking Forward: Building a Circular Future

Unilever's journey to zero waste is far from over.

The company acknowledges that achieving zero waste to landfill is just the first step.

Their ultimate vision is to create a truly circular economy – one where waste is virtually eliminated by designing products with recyclability in mind and ensuring resources are reused at every stage of the value chain.

Unilever's zero-waste journey is a powerful example of how large corporations can embrace sustainability and lead the way towards a more circular future.

It's a story that inspires innovation, collaboration, and a shared responsibility for protecting our planet.

Unilever could pull off zero waste to landfill when they consolidated, and outsourced their manufacturing waste management from multiple local contractors to a single, nationwide partner. This centralized approach streamlined operations and facilitated waste reduction efforts.

That’s the best way to do it.

If you are looking for a centralized, single, nationwide partner, you should look at Cercle to do it for you.

Book a discovery call and see how Cercle can help your brand go zero waste to landfill (ZWTL), and manage ALL your industrial wastes.